The Ultimate Guide To Bmerry Studio Alaskan Knives

Table of ContentsBmerry Studio Alaskan Knives - QuestionsIndicators on Bmerry Studio Alaskan Knives You Should KnowAlaskan Knives - The FactsWhat Does Bmerry Studio Do?

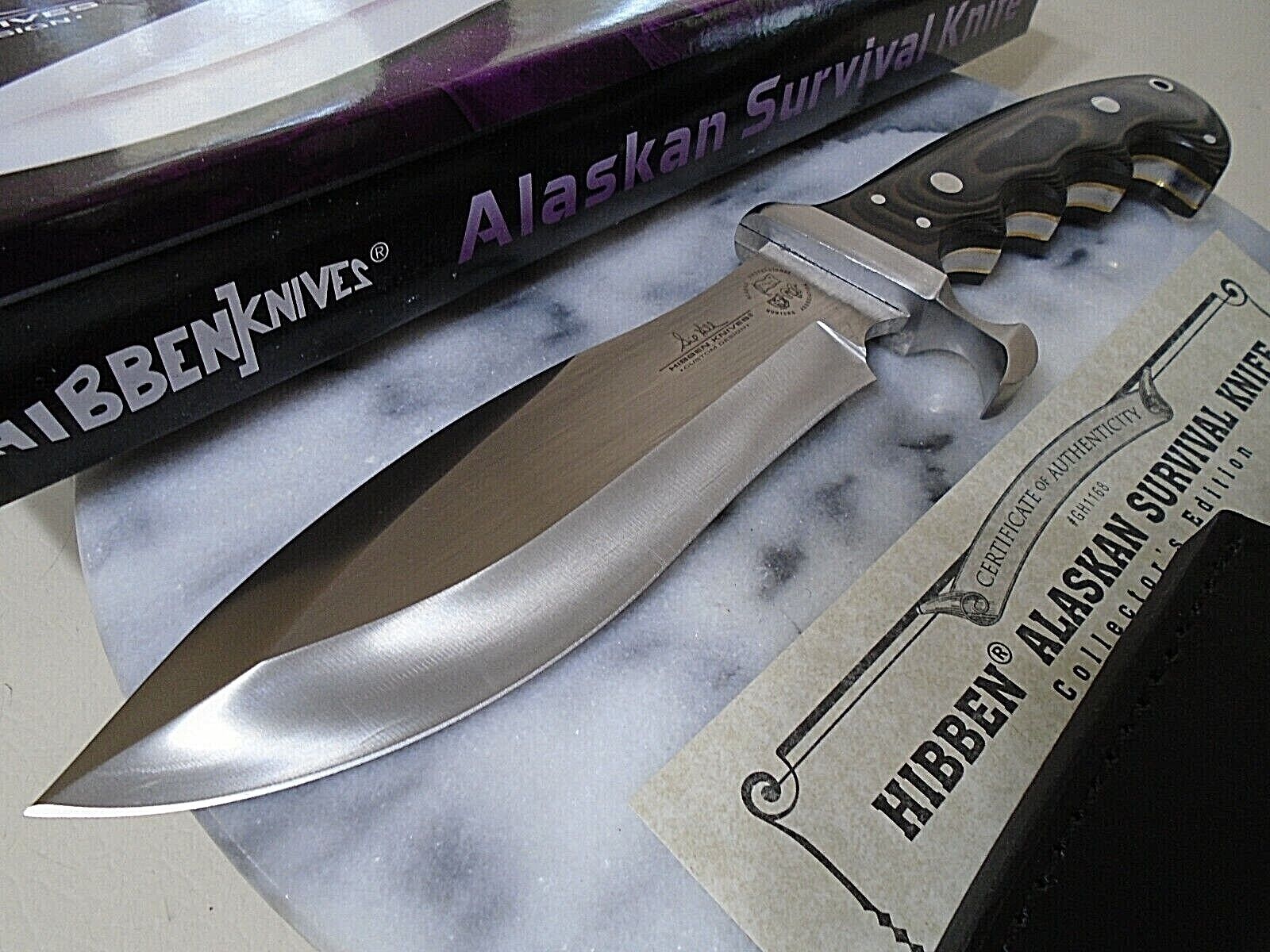

Being a simple person, and also having fairly excellent efficiency from our Cutco knives that we have formerly reviewed, this was my best knife for my tours as well as really did not assume two times regarding it. The Double-D edge that begins those knives seemed to hold an edge well, however certainly called for a developing after a few pets.Having some exposure to G10 scale product, I chose this for the take care of as I understood the product to be practically bulletproof. Gary was new to G10 too considering that he was drawn to the all-natural beauty and hardness of several of the unique hardwoods that he uses, but was greater than pleased to give me what I wanted.

The amount of times have you set your knife down in the expanse just a couple of feet away to then invest a couple of minutes searching for it, scraping your head assuming 'where might it have actually gone?!'.. Alaskan Knives.. high-vis deals with are a must. I picked a black/orange laminate ground in a 'avoid pattern' to provide the blade an attractive look over a solid color.

The 2nd lanyard loop on the bolster near the blade might aid you lash it to a stick if you were ever in a REAL pickle and required to style some kind of spear or whatnot. I also desired a bit of revealed steel past the back of the full-tang for striking, gouging, or whatever else you might need it for.

The Definitive Guide for Bmerry Studio

Enhanced durability (along with Gary's cryogenic 'warmth' treating of each and every blade he makes to a predetermined Rockwell solidity) suggests much less chipping of the side or tip (BMerry Studio). Stain resistance is likewise a huge factor for me, directly, since I want equipment that is low maintenance. I do not intend to have to be oiling my blade every night and also bothering with another thing while I'm utilizing it.

This steel is pricey, incredibly premium for this application, and also merely will not let you down. We could have conserved a couple of more dollars on the steel and also made a more affordable blade ... but why? To cover the bundle off, I asked for a shaped kydex sheath to safeguard the blade as well as maintain the weight down over a review leather design sheath.

I obtained the blade at the tail end of open season, just got to butcher one small deer with the knife, yet have utilized it around the house a little bit, handled it way also frequently, and revealed it to almost everyone I found. Given that I'm not the most significant individual running about, I handed the knife to a buddy that had significantly larger hands than I did, as well as quickly after obtaining a grip on it, he stated that the 'kick-up' at the back of the tang that was existing on the prototype was really awkward.

Bmerry Studio Alaskan Knives Can Be Fun For Anyone

Thus far, this is the only alteration that has been made prior to we determined to provide this to our viewers as well as followers. The pricing on this knife will certainly be $225 which I really feel is an excellent value for the top quality of the blade steel, the precision of the setting procedure, the hand-made nature of this thing, as well as the reality that it features a sheath as well as is prepared to include your pack and head to the area.

I think we pulled it off, and wish you like what you see. !! Written by Kyle I have actually been using Bolduc Knives for a couple years currently and also they will out do any kind of various other knife I have useful site ever utilized It is the only blade that I have ever before skinned and quartered a moose with without having to stop as well as develop.

At the side, he am around 10 to 15 thousands prior to putting a convex side on the blade. A lot of knife makers and store purchased knives are around 20 to 30 thousands thick at the edge before they place whatever design side on that they make use of normally convex. His edge design is shown on his site in the 'regarding my blades' or 'about my fillet blades' areas.

THE ALASKAN ULU BLADE IS MORE THAN SIMPLY A BLADE, IT'S A METHOD OF LIFE. basics A knife is a blade, however an Alaskan Ulu blade is something phenomenal.

A Biased View of Bmerry Studio

This functional blade made by the popular artist - Bob Merry can be made use of for numerous jobs inside and outside the house. To read more regarding the different ulu knives provided by numerous vendors throughout Alaska, take a look at the Voyij blade section. Despite which Ulu you buy it is recommended that the blade never be positioned in a dish washer.

Apply mineral oil or grease to the deal with to make sure a longer life. Needless to say, all knives require developing and the Ulu blade is no different. Blade World states that an Ulu knife can be developed in 10 mins using a sharpening rock and also, obviously, your boring blade.